After a year of live operation, 10 pure electric wide-body mining trucks handed over a satisfactory green, energy-saving and environmental protection answer sheet at Jiangxi De’an Wannian Qing Limestone Mine, finding a solid and feasible energy-saving and emission-reduction plan for green mine construction.

Low energy consumption and low cost

Maximize energy feedback

These wide-body mining trucks are equipped with Weihong Power’s 145kWh fast-charging power battery, dual motors with a rated power of 430kW, and a dedicated automatic transmission for Fast mining. In May 2021, Yanzhou Sinoma Construction Co., Ltd. officially put into operation in the De’an Wannianqing limestone mining project, and has been running stably for one year so far.

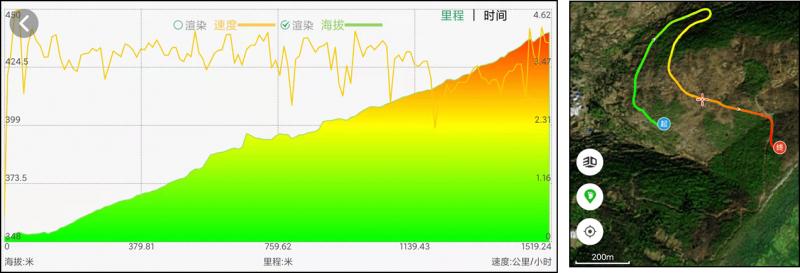

In terms of working conditions, the ore transportation road for pure electric wide-body vehicles is uphill with no load and downhill with heavy load. The route and slope are as shown in the figure below:

On the operation route of ore transportation, when a vehicle with a full load of about 90 tons goes downhill, the potential energy of the ore card is converted into mechanical energy and generated by the motor. The generated electricity is converted into AC-DC and stored in the power battery. At the same time, the braking of the vehicle is realized, and the loss of the brake pads is almost completely avoided, so the energy consumption can be greatly saved. When the average gradient reaches 6-7%, relying on the fast charging capability of the power system, the electric energy converted from potential energy is stored to the maximum extent. Able to achieve “0″ power consumption effect. Therefore, under this condition, even if the vehicle is equipped with a 145kwh battery, the vehicle can work continuously for 2-7 days on a single charge.

This batch of pure electric wide-body mining trucks is equipped with a motor with a rated power of 430kW and a peak power of 550kW. The maximum current (DC side) of the motor can reach 780A when downhill with a full load of 90 tons. If the battery cannot accept such a large current, the vehicle power Insufficient braking force requires mechanical brakes to supplement braking, which not only increases the power consumption of vehicle transportation, but also increases the wear of brake pads. The maximum charging current of the Weihong power fast charging battery equipped with this batch of mining trucks can reach 800A, which can maximize the power feedback, thus showing extremely low power consumption.

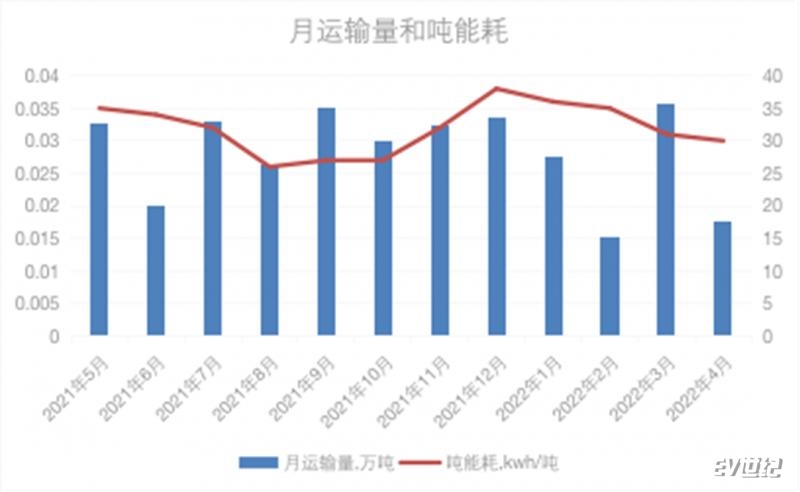

In addition , after statistical analysis of the two operating platforms , 10 wide-body mining trucks completed a total transportation volume of 3.39 million tons in one year of operation, with a total power consumption of 107,938kWh, with an average power consumption of 0.032kWh per ton of ore. According to the electricity price of 0.7 yuan/kWh, the transportation energy cost per ton of ore is about 2.24 cents, which is about 4% of the fuel vehicle.

High attendance, high reliability

Quickly recharge (supplement) electricity to improve operational efficiency

In line with the original intention of “doing more stones with less power consumption”, Yanzhou Sinoma has been looking for the most effective green transportation solution. The most efficient energy collection methods for pure electric mining trucks are fast charging (charging at the charging pile in the shortest time) and fast charging (maximizing the absorption of potential energy feedback). “A good horse with a good saddle”, the biggest feature of Weihong power battery is fast charging!

Long-term statistics show that at the charging end, the charging (refilling) time of a bicycle varies from 13 minutes to 32 minutes each time (the charging time varies depending on the remaining power), and the average time is about 20 minutes. Compared with the conventional slow charging time of about 1 hour, the micro macro fast charging greatly saves time and improves the attendance efficiency of the vehicle.

As we all know, the operating environment of the mining area is relatively harsh, and the vehicle has very strict requirements on the supporting battery, which puts forward higher requirements in terms of cycle life, charging speed, and battery performance. In the De’an Wannian limestone mine project, 10 vehicles are equipped with 10 drivers, which are basically single-shift production. Excluding the rest days of drivers, the vehicle’s attendance rate exceeds 98.5% (including soil dumping operations). During the 1-year operation period, the 10 dump trucks have experienced the wet and muddy spring, the high temperature and humidity in the summer, the strong storms and rain in the autumn and the low temperature and cold in the winter.

Jointly build green mines

Green transportation concept of sand and gravel aggregate industry

In recent years, with the implementation of the national “dual carbon” strategy, the development of green mine construction is in the ascendant. In order to further save energy and reduce emissions, according to the environment and operating conditions of its own sand and gravel aggregate mining area, the pure electric mining trucks invested by Yanzhou Sinoma Phase I have an attendance rate of over 98.5% and a “30-minute short-time charging, several days long-term operation”. Good results have been achieved, and great progress has been made in improving energy efficiency, protecting the mining environment, improving the convenience of driver control, controlling usage costs, and digital vehicle management and control.

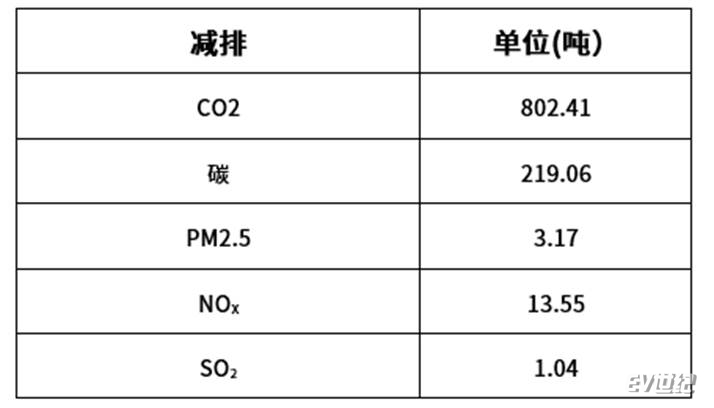

The data shows that in terms of emission reduction, this batch of mining trucks is driven by electricity, and 10 vehicles transport 3.39 million tons of ore a year, which directly reduces fuel consumption by about 305,100 liters and reduces the emission of various pollutants by more than 1,000 tons. At present, the emission reductions of various pollutants corresponding to the operation of pure electric mining trucks are as follows:

In the future, the planned production capacity of the De’an mining area will reach 6 million tons, and the pure electric wide-body mining truck will double the emission reduction of pollutants.

The operation of the fast-charging pure electric mining truck complies with the national “dual carbon” strategy. As the main goal, the circular economy development model is implemented according to local conditions, and a solid and feasible green development plan for the sand and gravel aggregate industry has been explored.

Post time: Jun-09-2022