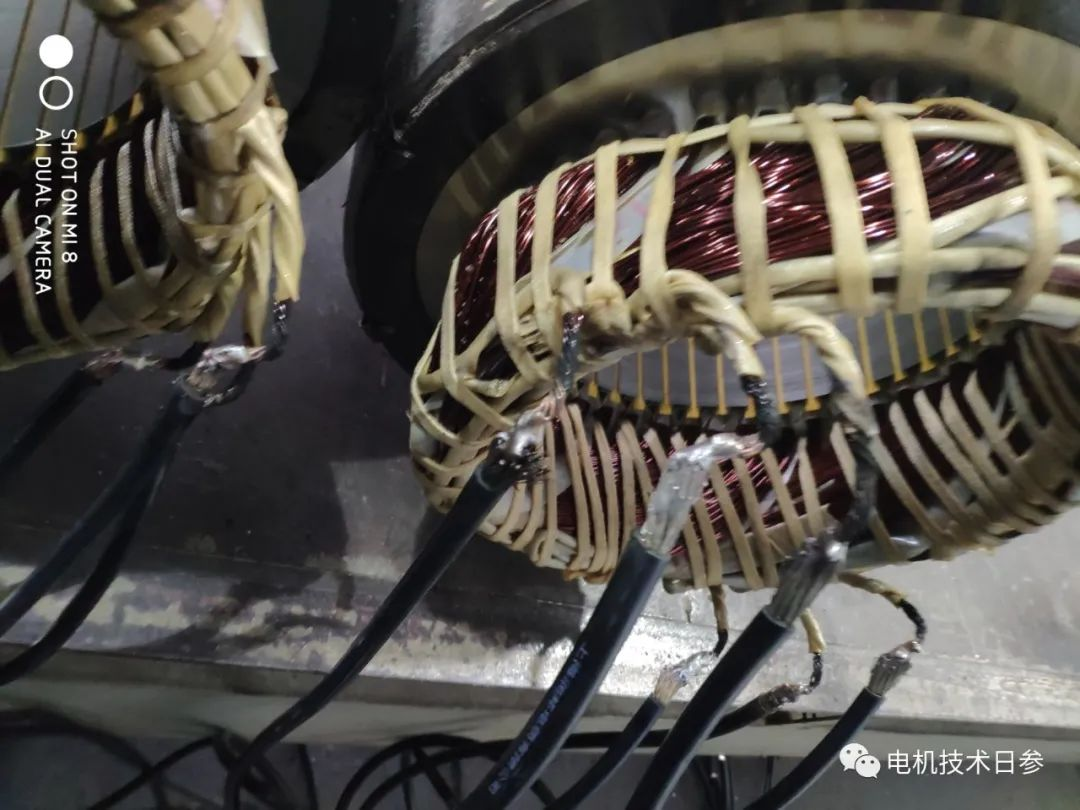

As an important component of the electrical part of the motor product, the lead wire of the motor involves electrical insulation and conductivity issues. In theory, as long as it is selected and installed according to the standard current density, the lead wire part will not have heating problems. However, in actual failure cases, such problems will occur from time to time. For this problem, we will discuss it from the specific failure characteristics.

(1) All lead wires have heating problems. For this problem, we are more concerned about the conductor diameter compliance and conductor material of the lead wires. If this problem occurs, in addition to individual installation errors, it should be more of a batch problem. This type of problem can basically be attributed to the product manufacturing quality of the motor.

(2) Individual lead wire heating problems. This problem is a relatively common fault feature reported during the motor operation process. In most cases, this fault is also accompanied by the burning of the terminal board. From actual fault cases, it can be found that this problem is caused by a local poor connection of the lead wire. It may occur at the connection position between the motor winding main line and the lead wire, and more often occurs at the fixation of the motor lead wire to the terminal, or the fixation link between the terminal and the terminal board.

Problems with the connection between the lead wire and the winding main wire, as well as the connection between the lead wire and the terminal, are typical manufacturing quality issues, but the connection between the wire and the terminal board is more directly related to the lead-in connection of the power cord.

During the motor manufacturing process, necessary anti-loosening measures have been taken in the terminal board fixing link, such as the use of anti-loosening elastic washers; however, during the motor installation link, if necessary anti-loosening measures are not taken, or if heat and vibration during motor operation lead to poor contact at the fixed position, heating problems will occur.

(3) Heating caused by low-voltage operation. This problem is similar to the problem of winding heating. When the motor is in long-term low-voltage operation, the current will increase significantly. For this reason, the lead wire must also withstand a large current. Especially when the lead wire diameter selection margin is not large, the large current density will cause the lead wire to heat up.

(4) Heating problem of wound rotor lead wire. This problem is a special fault of wound rotor motor. The cause of heating may be related to the welding of lead wire, the connection of collector ring, the matching of collector ring and carbon brush, and the material of carbon brush. It is also a relatively complicated problem. For this type of motor, ventilation and heat dissipation of collector ring is very important. For three-phase motor collector ring, the temperature of the three ring surfaces is obviously different, so it will also affect the temperature of rotor lead wire, but the degree of influence varies from motor to motor.

(5) Terminal material and cleaning issues. The terminal of the motor lead wire not only has the function of fixing the lead wire and the terminal board, but also must have good electrical conductivity. If the terminal material is poor, in addition to the problem of breakage during the installation process, the more serious problem is that the contact resistance of the connection part will increase, causing the lead wire to heat up. Another problem is that when the lead wire is dipped in the paint process with the winding, if the residual paint at the terminal is not cleaned up, it will also cause excessive local resistance and lead heating.

(6) Unreasonable structure of the terminal block. If the structure of the terminal block is unreasonable, it is likely to cause the connection parts to loosen during the operation of the motor, causing heating problems of the lead wires and windings.

In view of the above analysis, in order to ensure the operational reliability of motor products, the selection, fixation and subsequent maintenance of lead wires must be in place to prevent damage to the entire motor due to local failures.

Post time: Oct-31-2024