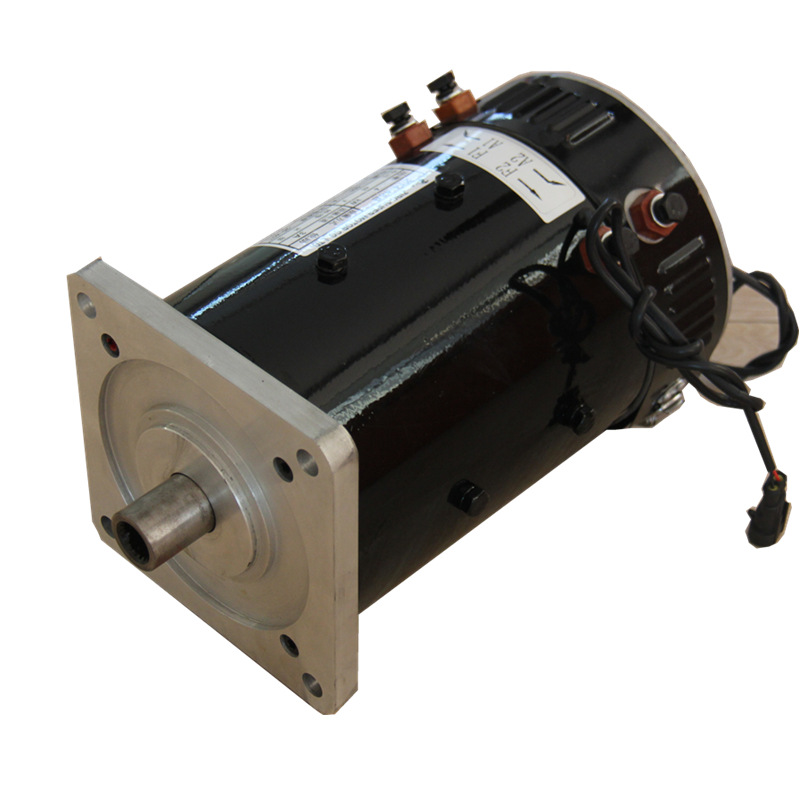

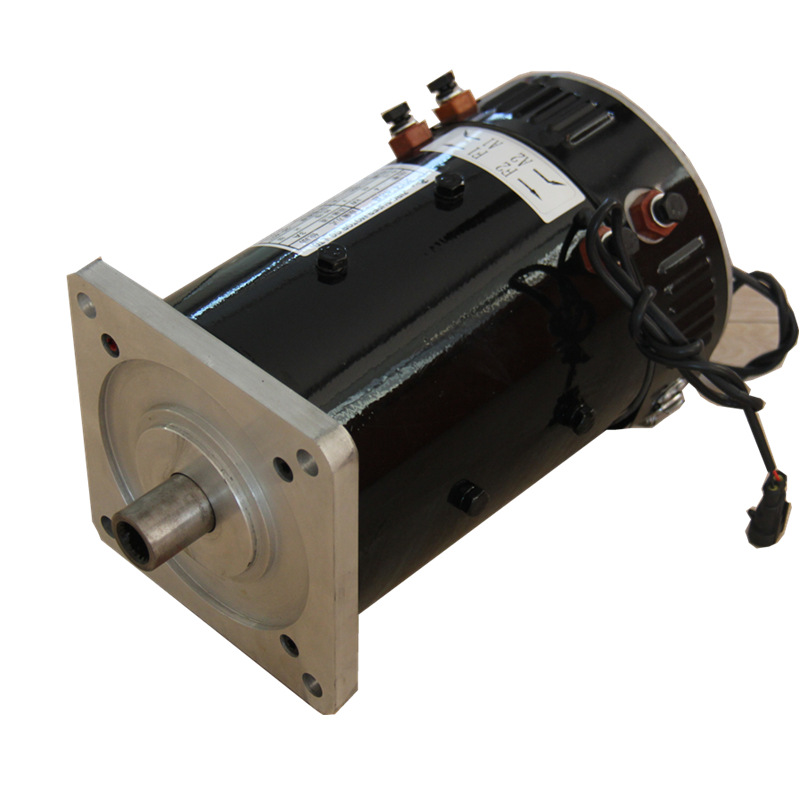

DC motor 4kw scooter electric car electric forklift motor

motor photo

motor photo

1. Reasonable structure, reliable performance, long service life

2. Large torque, strong overload capacity

3. High efficiency, long continuous running time

4. Good product consistency

5. Under the condition of constant torque output, the speed can be adjusted in a wide range .

6. The commutator has strong durability

7. Stainless steel brush spring

8. According to customer requirements, it can be equipped with temperature sensor and speed sensor

Instructions for use1. The user must follow the requirements of this manual.

Instructions for use1. The user must follow the requirements of this manual.

2. The motor should be stored in a ventilated, dry and clean environment. If the storage time is too long (six months), it is necessary to check whether the bearing grease is dry. The normal insulation resistance value of the test winding should not be

less than 5MΩ, otherwise it must be dried in an oven at 80±10℃.

3. For the bearingless motor at the shaft extension end, it should be adjusted after installation to check whether the rotor rotates flexibly and there is no rubbing phenomenon.

4. Check whether the motor connection line is correct and reliable.

5. Check whether there is oil on the surface of the commutator, and the brush should slide freely in the brush box.

6. The series excitation motor is not allowed to run under no-load power. If the user must run at no-load, the voltage should be controlled to be no more than 15% of the rated voltage.

7. There should be no corrosive gas in the cooling air.

Applicable environment

Applicable environment

1. The altitude does not exceed 1200M.

2. Ambient temperature≯40℃, minimum≮-25℃.

4. The motor is divided into fully enclosed type and open type. Fully enclosed can prevent foreign matter, dust and water from entering, and the open type can be more convenient for maintenance and replacement of the commutator and brushes.

5. The maximum allowable current of the motor for short-time overload is 3 times the rated value. At this time, the overload torque is 4.5 times of the rated torque, and the time should not exceed 1 minute.

packing list

packing list

Purpose/Field of Application

Purpose/Field of ApplicationMotor Care/Tips

1 The surface of the motor should be kept clean to prevent foreign objects from entering the interior of the motor. Frequently clean the greasy dirt on the motor. Check the carbon brush once every 5,000 kilometers and clean up the inside due to wear and tear.

Carbon brush powder, check whether the carbon brush is seriously worn or not connected, and replace the carbon brush in time. If the copper head of the motor rotor has worn scratches, it can be smoothed and cleaned with a fine sand cloth. Inspection every 20,000 kilometers

Check whether the motor bearing is short of oil (because the motor is often in a high temperature state, the gear oil will dry and evaporate), and it can be properly oiled for maintenance.

2 Try to avoid driving in harsh environments, especially in rainy days, do not drive in water, so as to avoid the rain exceeding the height of the motor, causing the motor to short-circuit and burn the motor.

Be careful of water entering the motor, immediately stop and turn off the power, let the water flow out automatically or assist the outflow, and the motor can be driven only when the accumulated water runs out and the motor is dry.