China Electric Car Motor Kit Supplier – Chemical pump motor XD56 series – INDEX

China Electric Car Motor Kit Supplier – Chemical pump motor XD56 series – INDEX Detail:

Product information

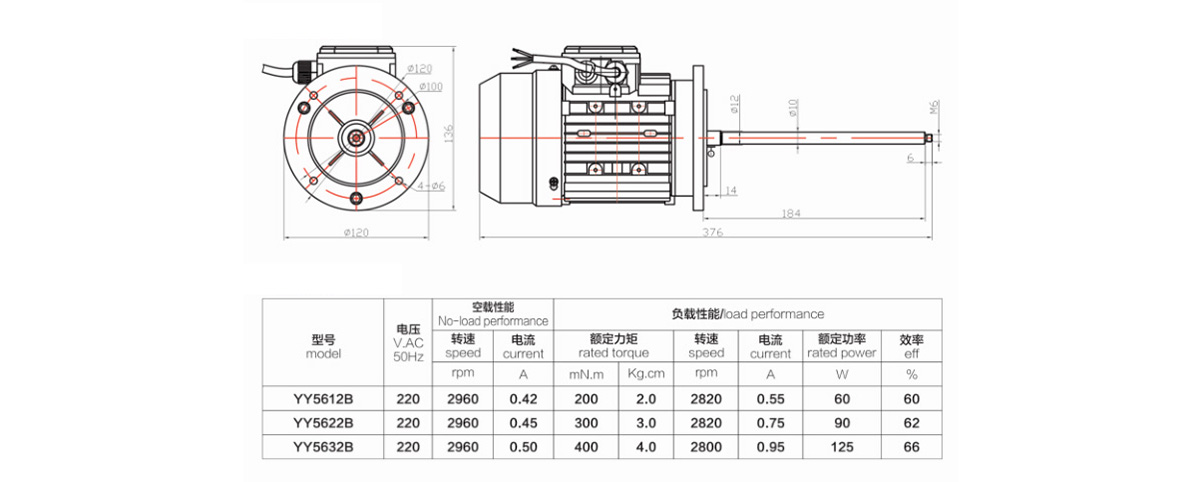

Model: XD56-B series

Name: Vertical long axis motor, 5 6 base size motor

Application: Chemical environmental protection, industrial equipment, pumps, electric actuators, etc.

Inspection points of vertical long shaft pump motor

Eight points of inspection of vertical long shaft pump motor:

1. Check whether the gap between the stator and the rotor of the vertical long-axis pump motor is the same in each direction, and whether there are debris in the gap, To prevent jamming or short circuit of the motor.

2. Check whether there is any sundries, especially metal conductive objects, in the wire groove of the vertical long-axis pump motor to prevent the motor from short-circuiting.

3. Check whether the nut of the rotating part is tightened. To prevent loosening due to vibration during operation, resulting in accidents.

4. Check the manual and automatic flexibility and reliability of the braking system, and whether the reset meets the requirements.

5. Check whether the upper and lower fan angles of the rotor of the vertical long-shaft pump motor meet the requirements to ensure the maximum cooling air volume for the motor.

6. Check whether the lubricating oil quality and oil level of the thrust bearing and guide bearing meet the requirements.

7. Pass the cooling water to check whether the tightness of the cooler meets the requirements and the correctness of the current display signal.

8. Check whether the bearing and motor stator thermometers meet the design requirements.

Product detail pictures:

Related Product Guide:

With a positive and progressive attitude to customer's interest, our enterprise continually improves our products excellent to meet the wants of customers and further focuses on safety, reliability, environmental requirements, and innovation of China Electric Car Motor Kit Supplier – Chemical pump motor XD56 series – INDEX , The product will supply to all over the world, such as: Hongkong , Miami , Bahrain , High output volume, top quality, timely delivery and your satisfaction are guaranteed. We welcome all inquiries and comments. If you are interested in any of our products or have an OEM order to fulfill, please feel free to contact us now. Working with us will save you money and time.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.